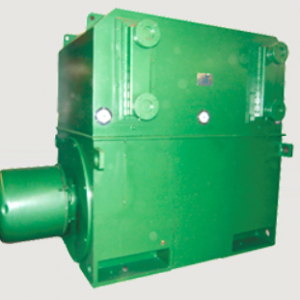

Y series high voltage ac motor use vacuum dipping and advanced drying equipment, high precision adjustment of rotor dynamic balance, 65 years of motor dipping experience, advanced technology, high efficiency, low noise, and low vibration. Reliable operation, convenient installation and maintenance, etc. The power rating, installation size, and electrical performance of the motor all comply with the relevant regulations of the national standard GB755 and IEC standards.

Y high voltage(3kv 6kv 10kv) ac motor is welded with all steel plates, the structure is reasonable, the self-contained shutters have good heat dissipation performance, and the VPI vacuum pressure dipping paint is used, which has superior insulation performance and long life. This series of motors can be used to replace the original J and JS series motors. Under the same motor power, small frame size production can be realized. At the same time, this series of motors are widely used and versatile, and can be derived from various types of motors. It is currently used by various industrial and mining enterprises.

- Experts team with many years experience to ensure the quality and technology of high voltage motors.

- All high voltage motors are tested for temperature rise and load of the system before leaving the factory.

- Vacuum dipping equipment and process.

The use of vacuum dipping equipment, more than two dipping processes, and 65 years of motor dipping experience ensure that the motor can maintain high insulation for a long time in a humid and dusty environment, reduce the number of maintenance, and extend the maintenance cycle by more than 1.2 times compared with similar products;

- Domestic advanced drying equipment and technology.

The use of advanced drying equipment and drying technology, pre-drying, drying, heat preservation, precise temperature and time control can effectively ensure the effective discharge of moisture, reasonable solidification and molding of the insulating paint, and ensure that the motor can perform in a humid and dusty environment Maintain high insulation level for a long time;

- Rotor dynamic balance adjustment equipment and technology.

With various specifications of high-precision rotor dynamic balance adjustment equipment, 65 years of adjustment experience, all specifications of the rotor are high-precision adjustment to ensure low vibration, low noise, reduce bearing wear, and ensure the reliability of the motor.

Reviews

There are no reviews yet.